The smart Trick of Bayside Laser That Nobody is Talking About

Wiki Article

Unknown Facts About Bayside Laser

Table of ContentsUnknown Facts About Bayside LaserThe Greatest Guide To Bayside Laser9 Easy Facts About Bayside Laser DescribedNot known Facts About Bayside Laser7 Easy Facts About Bayside Laser DescribedBayside Laser for Beginners

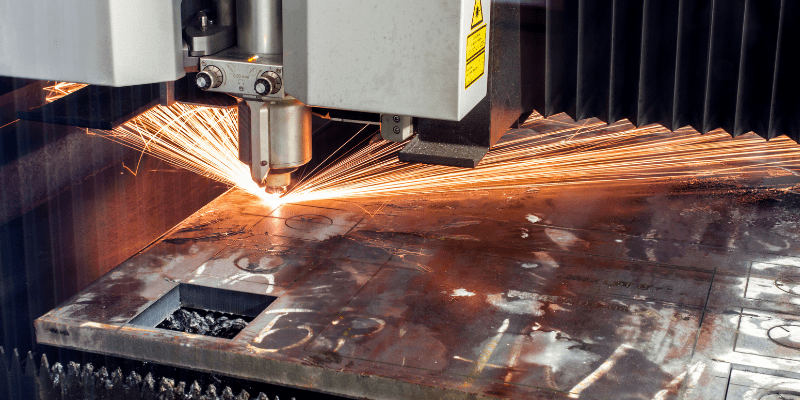

Flying optic machines should use some method to take into account the changing beam length from the close to field (near to the resonator) cutting to the far field (far from the resonator) cutting. Common methods for regulating this include collimation, flexible optics, or making use of a continuous beam size axis.

The power usage and also effectiveness of any kind of particular laser will certainly differ relying on outcome power and also running specifications. This will depend upon the kind of laser and also how well the laser is matched to the work at hand. The quantity of laser cutting power required, referred to as heat input, for a particular work depends upon the product type, density, process (reactive/inert) utilized, and also desired cutting price.

The smart Trick of Bayside Laser That Nobody is Talking About

The user can conveniently regulate the cut's deepness by adjusting the laser beam's power and also focus (http://www.place123.net/place/bayside-laser-capalaba-australia). Laser cutting is regular in metal, wood, plastics and fabrics.Whether you're seeking a brand-new or upgrading your procedures, laser cutting has wide applications, particularly in production. That claimed, here are 4 advantages of laser cutting: Laser cutting is just one of the most advanced, specific and exact methods for cutting materials. It can give a level of detail as well as accuracy that hand tools can never ever reach.

The 9-Minute Rule for Bayside Laser

The potential for laser reducing seems practically unlimited as it provides businesses top quality standard results in a portion of the moment. Laser-cutting modern technology is flexible as well as suitable with various products, ranging from wood and also natural leather to more difficult-to-cut metals. For these harder-to-cut products, laser cutters develop perfect accuracy cuts that are not offered with conventional cutting devices.Laser-cutting machines are as uncomplicated as most tools goes. Still, right here are four ideas to help get one of the most out of your process: With laser cutting, selecting the ideal material for the work content is vital. Depending on the designated application, different materials could be much more ideal than others depending upon aspects such as longevity and also safety.

Bayside Laser for Dummies

Clearly, laser cutting is a whole lot faster than the typical technique of reducing steel, yet is it much faster than other modern-day methods? Yes, it is. Laser cutting beats thermal cutting approaches such as plasma or fire in speed when cutting steel of as much as 10mm thick. That being stated, if you want the fastest outcomes you require to collaborate with the very best metal laser reducing makers such as those made use of by GF Laser that make use of the most up to date Trumpf Laser equipments (laser cutting near me).For those that need to reduce great deals of various forms, laser cutting is definitely the most eye-catching steel reducing option. With this technique of cutting metal, you do not require to alter tools to make different cuts as the precise same setup will accomplish multiple cutting work as long as the thickness continues to be the same.

During the laser cutting process, the beam made use of does not actually need to touch the product that is being cut, resulting in much less danger of damage. This implies that you will not need to sustain pricey repair services or delayed conclusion times as you may with various other approaches of cutting steel - cnc cutting service.

Everything about Bayside Laser

Laser reducing calls for less power than various other methods, utilizing generally 10k, W of power compared to 50k, W for various other cutting procedures. Of course, the safety and security of your employees is constantly at the forefront of your mind and laser reducing provides among the best methods of cutting steel.That accurate point creates a very high strength that can reduce through the product. The whole procedure is managed by, you guessed it, a computer. Behind that computer system is typically a licensed professional that aids assist the procedure so everything runs efficiently. Contrasted to traditional reducing methods, laser cutting deals a number of advantages.

Unlike numerous producing equipments, laser cutters generally do not need you to switch out various devices for whatever cut you desire. Laser cuttings use extreme accuracy contrasted to various other standard cutting approaches.

Top Guidelines Of Bayside Laser

Depending upon exactly how a laser cutter is set up, you're typically going to observe potentially a tiny burr on a component. Typically, it's not essential to remove the burr, yet it depends upon the material, its thickness and various other factors. Oh yes, this is just one of the ideal components of utilizing a laser cutter; convenience.

No job is as well made complex for the laser cutter. A really narrow area of material is conveniently navigated by the high-powered laser and also is very seldom distorted or distorted. Jobs are not simply limited to sheet metal with a laser cutter. Lasers have the ability to cut stainless-steel, aluminum, copper, and brass.

Report this wiki page